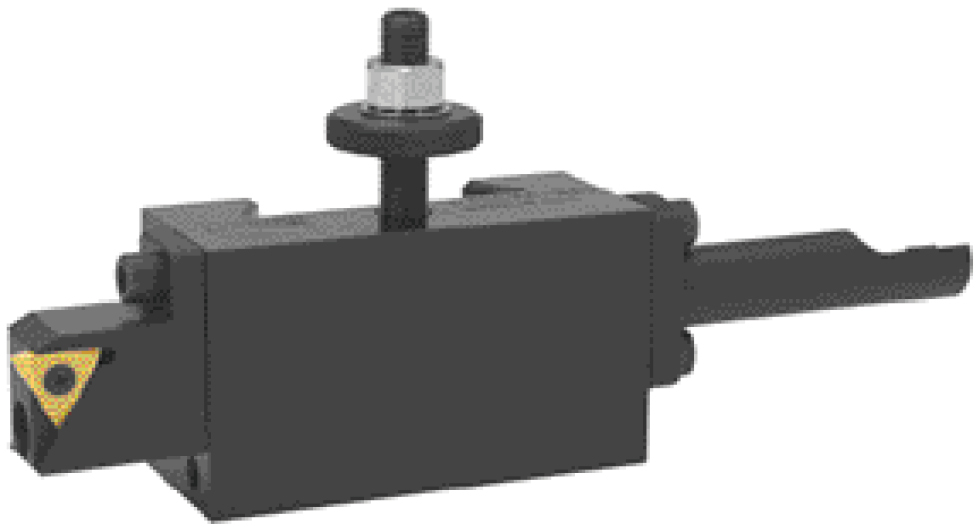

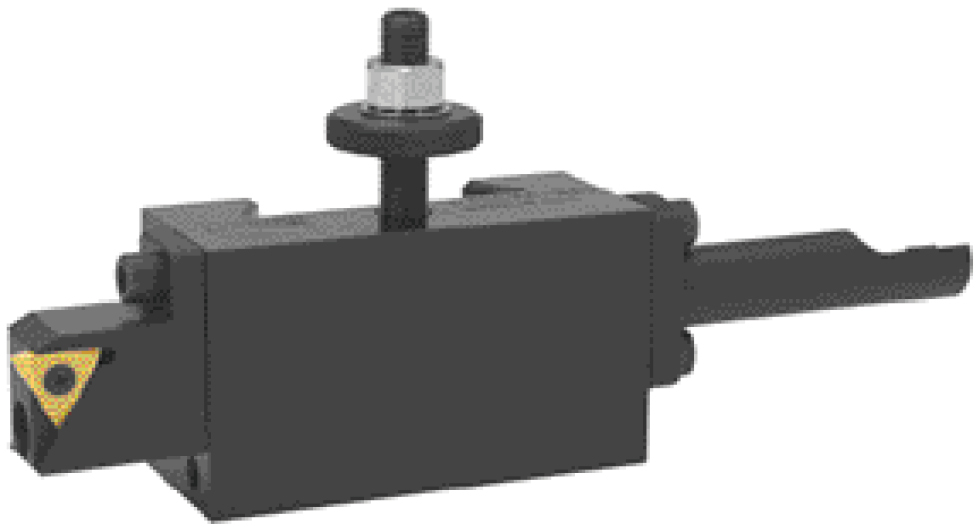

Quadra Indexing Tool Holders

Dorian Tool’s Quadra Indexing Tool Holders are precision crafted from 4140 Chromium-Molybdenum Alloy Steel. Our quadra Indexing tool holders undergo a special heat treatment process to ensure surface protection and minimal cutting vibration.

With quick-change mounting and interchangeability within .0001”/.00127mm, these tool holders offer unparalleled accuracy. From turning and facing to heavy-duty drilling and threading, our quick change holders cater to a wide range of machining operations. Take a look at our diverse range, including bore, cutoff, threading, and collet holders, designed to meet your specific needs with reliability and efficiency. Pairs perfectly with our Quick Change Tool Posts.

Image

Structure Specifications

Features

Application

-

Toolholders are Built with 4140 CromiumMolybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Over size Capacity for large Indexable Square Shank

-

For Multi Turning Operation, when a Square Shank is used

-

Toolholders are Built with 4140 CromiumMolybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration Quick Change Mounting

-

Toolholder Flat, has a “V” Groove to hold a Round Boring Bar

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Over size Capacity for large Indexable Square Shank

-

Capeble to hold Square Shank & Boring Bar

-

Wide Range Turning Operation, when a Square Shank & Boring Bar are used

-

Toolholders are Built with 4140 CromiumMolybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Built with DOUBLE Boring Bar Locking System

-

360° Collar Locking System

-

Self Centering Screw Lock System

-

For Boring Bar with & without Flats

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

For All the Boring Operation when a Round Tool is used

-

Toolholders are Built with 4140 CromiumMolybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Built with DOUBLE Boring Bar Locking System

-

360° Collar Locking System

-

Self Centering Screw Lock System

-

For Boring Bar with & without Flats

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

For All the Boring Operation when a Round Tool is used

-

Toolholders are Built with 4140 CromiumMolybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Built with DOUBLE Boring Bar Locking System

-

360° Collar Locking System

-

Self Centering Screw Lock System

-

For Boring Bar with & without Flats

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

For All the Boring Operation when a Round Tool is used

-

Toolholders are Built with 4140 Chromium-Molybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

All the Drilling, Reaming, Tapping, Operation using Drill Chuck or Morse Taper

-

Heavy Duty Drilling Operation

-

Toolholders are Built with 4140 Chromium-Molybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Holds Industry Standard Sizes Cut-Off Blades

-

Cut-Off Operation

-

Grooving Operation

-

Toolholders are Built with 4140 Chromium-Molybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Quick Change Mounting

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Holds OD Threading Cartridge

-

Holds 1D Threading Bar

-

Easy to Set-Up, Simple to Use

-

Uses Industry Style Threading Inserts

-

O.D .and I.D. Threading

-

Toolholders are Built with 4140 Chromium-Molybdenum Alloy Steel

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

2 Pieces Construction, for Precise Parallelism Calibration

-

Supplied with Rohm Drill Chuck

-

Quick Change Mounting

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Holds a 1/2”/12.7mm capacity, precise, Strong & Rigid Drill Chuck

-

Versatile for Multi Operation

-

Drilling, Boring, Reaming, Threading

-

Using Standard Tools or Special Tool

-

Special Heat Treat Process to protect Surface, & minimize Cutting Vibration

-

Toolholder Interchangeability within .0001”/.00127mm

-

Toolholder Squareness and Parallel .0005” x inch/.00127 mm

-

Holds 5 C Collets Series

-

Accept, Round, Square & Hexagonal Collets

-

Versatile for Multi Operation

-

Drilling, Boring, Reaming, ThreadingTurning

-

Using Standard Tools or Special Tool

Image | Structure Specifications | Features | Application |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

|

|

|

| |

|

|

| |