How to Choose the Right Tool Holder for Your Machining Needs

In the world of machining, precision is key. Every component of the machining process plays a crucial role in determining the quality and accuracy of your final product. Out of all these components, choosing the right tool holder for the job is a critical element that directly impacts quality and output.

In this guide, we’ll review the significance of tool holders, explore the different types available, and provide essential tips for selecting the right tool holder to meet your specific machining needs.

We’ll be taking a look at:

Machine Tool Holder Basics

Different Types of Machine Tool Holders

Things to Consider When Selecting a Tool Holder

High Precision Dorian Tool Holders

The Basics: What’s a Machine Tool Holder?

Before jumping into the nuances of selecting the right tool holder, it’s essential to understand what exactly a tool holder is and its role in the machining process. Simply put, a tool holder is a device used to secure cutting tools in a machine tool’s spindle.

They create a strong and steady connection between the tool and the machine, which makes cuts accurate and smooth. To ensure the correct alignment and symmetry of your cutting tools while machining, turn to a tool holder! But are they all the same and will just any tool holder work?

Well, tool holders come in various designs and configurations to accommodate different types of cutting tools, such as drills, end mills, and inserts. They’re typically made from materials such as steel, carbide, or ceramic to withstand the rigors of machining while allowing dimensional stability and accuracy.

The quality of materials sourced, as well as the manufacturing process as a whole, are the two biggest things between creating a great tool, or just an ‘ok’ one.

For those wanting to dive deeper into these nuances, you can take a look at our comparative guide on popular tooling suppliers. Everyone else, let’s continue!

Which Tool Holder is Right for Me? Different Types:

When selecting the right tool holder for your machining needs, several factors come into play. These factors include the type of cutting tool, machining application, machine configuration, and desired level of precision. Here are some common types of tool holders to consider:

Quick-Change Tool Holders: The quick change tool holder revolutionized machining operations by allowing swift tool changes. This vastly amplifies efficiency in multi-tool setups, drastically reducing downtime.

Collet Chucks: Collet chucks are versatile tool holders that use collets to securely grip round shank cutting tools. They offer excellent concentricity and are ideal for high-speed machining applications.

End Mill Holders: Designed for straight shank end mills, these holders are specifically designed to hold end mills with straight shanks. They provide rigid clamping and precise alignment, making them suitable for milling operations.

Shell Mill Holders: Shell mill holders are used to hold shell mills and face mills with large diameter cutting inserts. They provide robust clamping and are well-suited for heavy-duty machining tasks.

Hydraulic Chucks: Hydraulic chucks use hydraulic pressure to clamp cutting tools, providing superior gripping force and vibration damping. They are ideal for high-precision machining applications.

Shrink Fit Holders: Shrink fit holders use thermal expansion to grip cutting tools, ensuring excellent runout accuracy and rigidity. They are commonly used in high-speed machining and hard milling applications.

Morse Taper Holder: Morse Taper Holders are used in creating precise holes or in threading operations. They’re specifically designed with tapered shanks, which allows for secure and reliable tool retention during the machining operations. This tapered design provides a snug fit between the holder and the machine spindle.

Things to Consider When Selecting a Tool Holder

When choosing a tool holder for your machining needs, it’s essential to consider several key factors when choosing the right holder for the right job. Taking the time to evaluate these factors will significantly impact your success and productivity, and save you money!

Specific Machining Needs: Evaluate the specific requirements of your machining project, including material type, cutting parameters, and desired surface finish. This initial evaluation guarantees that the selected tool holder is perfectly suited to tackle your specific machining needs.

Holder Accommodates Incremental Gage Lengths: Ensure that the tool holder can accommodate incremental gage lengths to accommodate various tool lengths and machining setups. This flexibility allows for seamless adjustments and optimal tool positioning, enhancing overall machining efficiency.

Dual Contact: Dual contact tool holders provide enhanced stability and rigidity by making contact with both the spindle and the tool shank. Consider using dual contact holders for demanding machining applications, as they offer superior performance and precision.

Consider Machine and Spindle: Take into account the specifications of your machine tool and spindle, including taper size, spindle speed, and maximum tool diameter. Matching the correct tool holder to the machine and spindle specifications ensures compatibility and optimal performance.

Rigidity: Look for tool holders with touch construction and clamping mechanisms to minimize deflection and vibration during machining operations. Enhanced rigidity ensures stable tool positioning and precise cuts, resulting in superior machining quality. This is where the quality of the machine tool supplier comes into play.

Accuracy: Choose tool holders with tight manufacturing tolerances to ensure precise tool positioning and alignment. This attention to detail guarantees consistent and accurate machining results, critical for achieving desired part dimensions and surface finish. The key to precision machining!

Power: Consider the power and torque requirements of your machining needs and select a tool holder capable of handling the workload, without compromising performance. Choosing a tool holder that matches the power requirements ensures efficient and reliable machining operations.

Balance: Choose balanced tool holders to minimize spindle load imbalance and ensure smooth operation at higher speeds. Proper balance reduces vibrations and enhances stability, resulting in improved machining performance and tool life.

High Precision: Most Popular Dorian Tool Holders

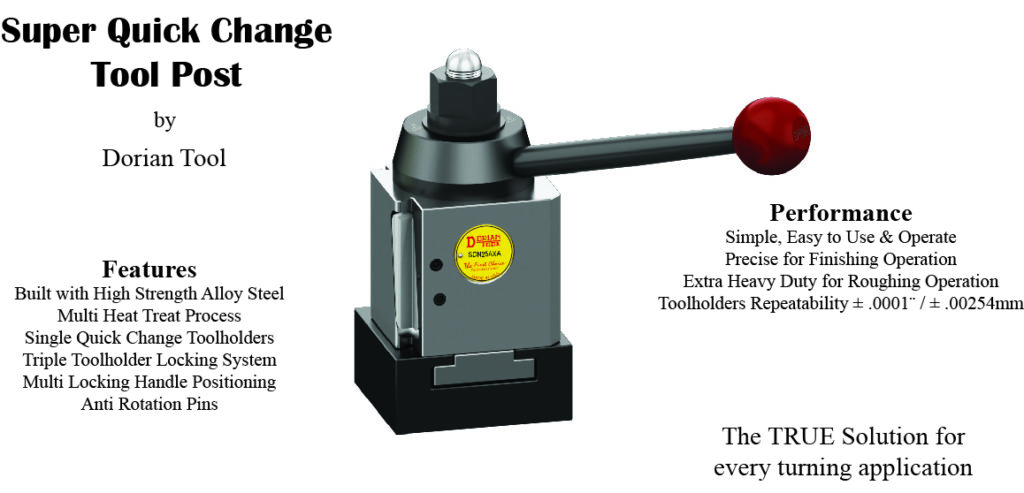

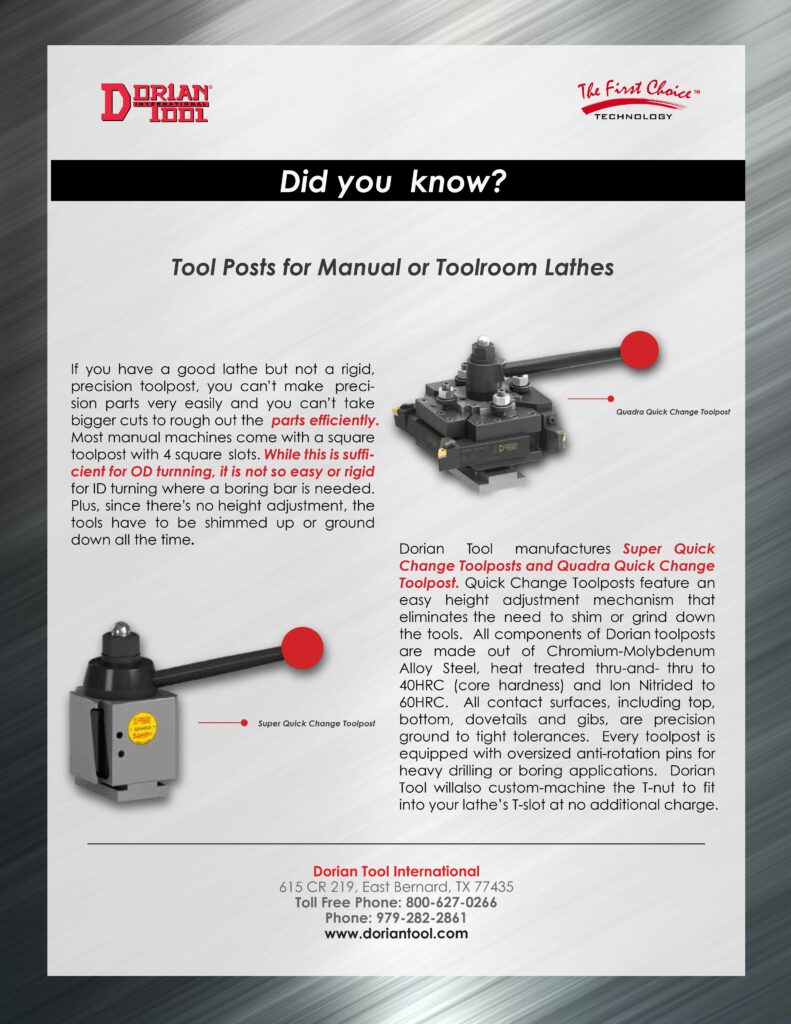

In the realm of machining precision, few tools rival our Dorian Quadra and SDN Quick Change Toolholders. Designed to excel in demanding machining environments, they offer unparalleled rigidity and stability, making them indispensable for precision machining tasks.

Incorporating a specialized low-temperature heat treating process, Dorian tool holders not only resist wear but also effectively dampen cutting vibrations, ensuring consistently high-quality results.

Quadra and SDN Quick Change Toolholders

The quadra and SDN quick change tool holders represent the pinnacle of machining precision and durability. Crafted from 4140 Chromium-Molybdenum High Strength Alloy Steel, these tool holders ensure unmatched rigidity, stability, and performance in machining operations.

Employing a specialized low-temperature heat treating process, the surface of our tool holders is fortified against wear while effectively dampening cutting vibrations. With a range of sizes from SDN25AXA to SDN60EA, accommodating tool capacities from 3/8 inch to 1 ½ inch, and featuring a dual locking system for maximum stability.

Quadra® Tool Post Indexing System

The Quadra® Tool Post Indexing System redefines ease and precision in multi-operation setups. With patented indexing and locking technology, users can effortlessly rotate the tool post to desired positions with a simple push-and-pull mechanism.

Each quick-change toolholder is independently locked by individual cams, ensuring secure and precise tool placement. From OD chamfering to combination OD and ID operations, this system offers versatility with pre-loaded positioning index pins and a super precise ball-bearing locking system.

Built for heavy-duty applications, these tool posts and toolholders boast heat-treated high-strength alloy steel construction and precision-ground locking stations. They feature a positive locking system with zero backlash, delivering unparalleled rigidity, accuracy, and repeatability down to .0001 inches.

A Note from Dorian on Tool Holders:

At Dorian Tool, we take pride in our commitment to quality, innovation, and American craftsmanship. For over 30 years, we’ve been at the forefront of the machining industry, designing and manufacturing high-precision tooling solutions right here in the USA.

Our commitment to American manufacturing not only boosts our economy, but also ensures the highest quality control standards throughout our operations. In fact, North America accounts for 45% of all global tool holder production, and we take pride in contributing significantly to that statistic. By keeping our operations domestic, we can meticulously oversee every phase of the process, from material sourcing and manufacturing to final inspection.

We never cut corners, and anyone that has ever used a Dorian tool holder can speak to their durability, reliability, and precision. This along with our loyal customers over the long years is why Dorian Tool is the preferred choice for machinists with an eye for precision and manufacturers worldwide.

We hope this has been informative and helpful in your search for the right tool holder. By evaluating the above considerations, you should now be able to determine which tool holder is right for the job at hand. If you have any questions or are still not sure which tool holder is best for you, don’t hesitate to give us a call; we’re here to help every step of the way!